Have you ever thought where are the ingredients coming from to make your daily supplements? In the relentless pursuit of peak physical performance, millions of Americans turn to muscle supplements. The ritual is familiar: the satisfying clink of the metal scoop, the billowing cloud of powder, the vigorous shake, and the final gulp of a milkshake-like drink promising repair, growth, and strength. We are a nation obsessed with optimization, and a robust supplement industry, valued at over $40 billion, has risen to meet this demand. But in our focus on the end product—the macros, the flavors, the brand promises—we rarely pause to ask a fundamental question: Where does this stuff actually come from?

The journey of a single scoop of protein powder is a complex global odyssey, a story woven through sprawling industrial farms, massive chemical processing plants, and international shipping lanes. It’s a narrative that touches upon agricultural subsidies, Chinese manufacturing dominance, and intricate supply chains that are often obscured from the consumer. To understand the truth behind your tub of gainz is to pull back the curtain on a fascinating, and at times unsettling, global enterprise.

This is the deep dive into the origins of your muscle supplements.

The King of Supplements: The Whey Protein Trail

Let’s start with the undisputed monarch of the supplement world: whey protein. A byproduct of cheese production, whey’s journey begins not in a lab, but on a dairy farm.

1. The Dairy Farm: The Primary Source

The vast majority of whey protein consumed in the U.S. originates from American dairy farms. The U.S. is a global dairy powerhouse, with Wisconsin and California leading production. Here, the life of a supplement begins with a cow. The quality of the milk, and by extension the initial whey, is influenced by the cow’s breed, diet, and overall health. Milk from grass-fed cows is often marketed as a premium source for whey, claiming a better fatty acid profile.

Check also: 20 biggest gym supplements producers in USA

This raw milk is collected and transported in massive, refrigerated tankers to cheese manufacturing facilities. This is the first critical link in the chain, and it’s almost entirely domestic.

2. The Cheese Factory: The Birth of Whey

At the cheese plant, enzymes (like rennet) or acids are added to the milk, causing it to coagulate. The solid curds are separated and pressed to become cheese. The leftover liquid—a watery, yellowish fluid containing lactose, proteins, vitamins, and minerals—is the whey. For decades, this whey was considered a problematic waste product, often discarded or used as low-grade animal feed. The rise of the fitness industry transformed this “waste” into a valuable commodity.

3. The Processing Plant: From Liquid Whey to Powdered Gold

The liquid whey is swiftly transported to specialized processing plants, many of which are operated by a few major players like Glanbia, Leprino, and Hilmar Ingredients. Here, it undergoes a transformative journey:

- Pasteurization: The liquid whey is heated to kill any harmful bacteria.

- Filtration: This is the most crucial step. Using a series of increasingly fine filters in a process called microfiltration or ultrafiltration, the components of whey are separated.

- Whey Concentrate (WPC): This form undergoes less intensive filtration, retaining more of the lactose and fat. The protein percentage can range from 35% to 80%.

- Whey Isolate (WPI): To create isolate, the whey undergoes further processing, often using ion-exchange or cross-flow microfiltration, to remove almost all the lactose and fat, resulting in a product that is typically 90%+ protein.

- Whey Hydrolysate: This is pre-digested (hydrolyzed) whey, where large protein chains are broken down into smaller peptides for allegedly faster absorption.

After filtration, the resulting liquid is spray-dried in massive towers where it is transformed into the fine powder we recognize. It is then packaged in enormous bags or boxes and sold as a bulk ingredient.

4. The Supplement Company: The Final Stop

This is where branding enters the picture. Supplement companies, from industry giants to garage-startup brands, purchase these bulk whey proteins from the processors. They then engage in “contract blending.” They create their proprietary flavor blends (a complex mix of artificial sweeteners like sucralose, acesulfame potassium, and natural flavors, cocoa, etc.), and send their “recipe” to a contract manufacturer. The manufacturer mixes the bulk whey with the flavors, vitamins, and other ingredients, packages it in the branded tubs, and ships it to distributors or directly to consumers.

The key takeaway: While your whey protein’ story may be marketed with images of rugged American farms, its quality is largely determined at the processing stage. The brand on the tub is often the last in a long line of contributors.

Optimum Nutrition Amino Energy – Pre Workout with Green Tea BCAA Amino Acids

Ignite your energy and focus with Optimum Nutrition Amino Energy, the ultimate all-in-one pre-workout and recovery formula designed to power your day—whether you’re hitting the gym, the track, or just need a mental boost.

The Plant-Based Paradox: A Truly Global Supply Chain

As the plant-based movement grows, so does the demand for vegan proteins like pea, rice, and soy. The supply chain for these is even more globally dispersed and complex than that of whey.

- Pea Protein: The United States, particularly the Northern Plains states like North Dakota and Montana, is a significant producer of yellow peas. However, a vast portion of the world’s pea protein processing is dominated by companies in France (Roquette) and Canada (PURIS, which has a major partnership with Cargill in the U.S.). The peas are grown, harvested, and then shipped to these specialized facilities where they undergo a dry or wet fractionation process to separate the starch from the protein, resulting in a concentrated powder. China is also a massive grower of peas and is ramping up its processing capabilities, becoming an increasingly important source for budget-conscious supplement brands.

- Rice Protein: The journey of rice protein is almost inextricably linked to Asia. While the U.S. grows rice, the economic scale of rice protein production is centered in Europe and Asia. Brown rice is treated with enzymes to separate the carbohydrates and fiber from the protein. Many U.S. brands source their organic rice protein from Europe, where manufacturing standards are perceived as stringent.

- Soy Protein: The U.S. is the world’s second-largest producer of soybeans, behind Brazil. Vast swathes of the Midwest are dedicated to soybean cultivation. The processing of soy into soy protein isolate is a major industrial operation, with companies like ADM and DuPont being key players. The beans are cleaned, cracked, dehulled, and rolled into flakes. The oil is extracted, and the defatted flakes are then processed to isolate the protein. While the supply chain for soy can be very domestic, many consumers and brands have shied away from soy protein due to concerns about phytoestrogens and GMOs, unless explicitly labeled as non-GMO or organic.

The plant-based pipeline reveals a critical truth: “Made in the USA” on a tub of vegan protein does not mean all the ingredients originated stateside. The raw materials may have been grown in North America, processed in Europe, and then blended and packaged in the U.S.

The Synthetic Engine: Creatine, BCAAs, and Pre-Workout Components

This is where the story moves from the farm to the factory floor. Many staple supplements are not extracted from food but are synthesized through chemical and fermentation processes.

- Creatine Monohydrate: The vast, overwhelming majority of the world’s creatine is manufactured in China. The synthesis of creatine is a chemical process, originally involving sarcosine and cyanamide, which requires significant chemical manufacturing infrastructure. China’s dominance in this sector is due to its established chemical industry, lower production costs, and economies of scale. While there are a few producers in Germany and the U.S., they cannot compete on price, making Chinese-sourced creatine the standard for nearly every supplement brand globally. This is a fact many brands are reluctant to highlight on their packaging.

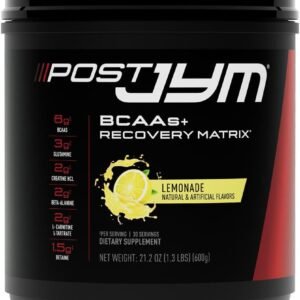

- Branched-Chain Amino Acids (BCAAs): L-Leucine, Isoleucine, and Valine are typically produced through microbial fermentation. This involves using genetically modified bacteria or yeast that are engineered to overproduce these specific amino acids. The fermentation tanks are fed a carbohydrate source (often corn syrup from the U.S.), and after fermentation, the amino acids are extracted and purified. While the science is global, China and Japan are major hubs for the fermentation and synthesis of amino acids used in supplements and pharmaceuticals.

- Pre-Workout Ingredients: Your tub of pre-workout is a global cocktail.

- Caffeine: This is often synthesized chemically or extracted from green coffee beans. The source can vary, but China is a major producer of synthetic caffeine.

- Beta-Alanine: Like creatine, this is primarily synthesized in China.

- Citrulline Malate: Often produced via fermentation or chemical synthesis, with China being a key source.

- Betaine: Typically derived from sugar beets, with sourcing from the U.S. or Europe.

The pattern is clear: for synthesized ingredients, the global manufacturing epicenter is frequently China. This reliance creates vulnerabilities, as seen during supply chain disruptions like the COVID-19 pandemic or trade disputes, which can lead to shortages and price spikes.

The Unspoken Truths: Sourcing, Safety, and Transparency

Understanding these global pipelines forces us to confront several critical issues.

1. The Transparency Problem: Most supplement brands are marketing companies, not manufacturers. They are not required to list the country of origin for each ingredient on their label. A brand can legally claim “Made in the USA” if the final blending and packaging occurred domestically, even if 100% of the key active ingredients were sourced from China. This lack of granular transparency is the industry’s dirty secret.

2. Quality and Purity Variance: The quality of an ingredient can vary dramatically based on its source. China’s chemical industry has faced scrutiny over quality control and adulteration in the past. This is why reputable brands invest in third-party testing from organizations like NSF International, Informed Sport, or USP. These verifications test for heavy metals, contaminants, and accurate ingredient levels, providing a crucial layer of safety. A brand that is transparent about its third-party testing is generally a safer bet than one that is not.

3. The “Grass-Fed” and “Non-GMO” Marketing: These labels are meaningful, but they are not guarantees of superior efficacy. “Grass-Fed Whey” does imply a different, often more natural, upbringing for the dairy cows, which can influence the fat profile of the initial whey. “Non-GMO” is important for plant-based proteins, ensuring the source crops weren’t genetically modified. However, these are often marketing pillars used to justify a premium price, and their tangible impact on muscle growth for the end consumer is often overstated.

C4 Ripped® Pre Workout Powder

How to Be an Informed Consumer

In a market saturated with choice and obscured by complex supply chains, how can you make an informed decision?

- Look Beyond the Marketing: Ignore the dramatic graphics and athlete endorsements. Turn the tub over and read the supplement facts and the fine print.

- Prioritize Third-Party Testing: This is the single most important factor for purity and safety. Look for seals from NSF, Informed Sport, USP

- Research the Brand’s Transparency: Does the brand openly discuss its sourcing on its website? Do they provide detailed information about their manufacturing partners and quality control processes? A transparent brand is a confident brand.

- Understand “Proprietary Blends”: Be wary of these. They allow companies to hide the exact doses of individual ingredients behind a collective weight, often “dusting” expensive ingredients with cheaper fillers to cut costs.

- Consider Your Priorities: Decide what matters to you. Is it absolute lowest cost, which often means heavier reliance on the most economical global sources? Or is it supporting domestic agriculture and stringent manufacturing, which may come at a higher price?

The journey of your muscle supplement is a testament to modern globalized industry. It is a story of agricultural abundance, chemical ingenuity, and logistical marvels. But it is also a story that requires a discerning eye. By understanding the complex pipeline that delivers protein to your shaker cup, you empower yourself to look past the marketing haze and make choices based not on fantasy, but on the tangible, global reality of your pursuit of strength. The truth is in the tub, but you have to know how to read it.